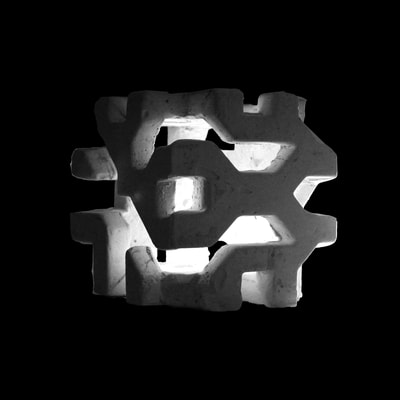

cube

3D TESSELLATION

FIRST YEAR STUDIO—TEXAS A&M UNIVERSITY

SPRING 2016

INSTRUCTORS: ALIREZA BORHANI + BARA SAFAROVA

COLLAB : JESSIE BULLARD + MICHAEL VANDERMATE

FIRST YEAR STUDIO—TEXAS A&M UNIVERSITY

SPRING 2016

INSTRUCTORS: ALIREZA BORHANI + BARA SAFAROVA

COLLAB : JESSIE BULLARD + MICHAEL VANDERMATE

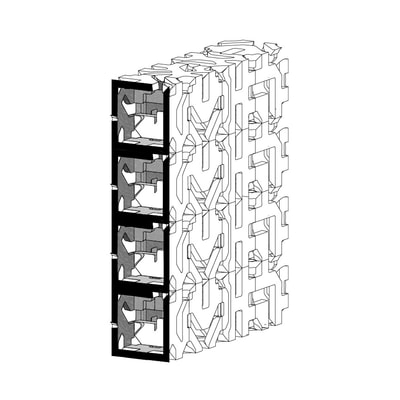

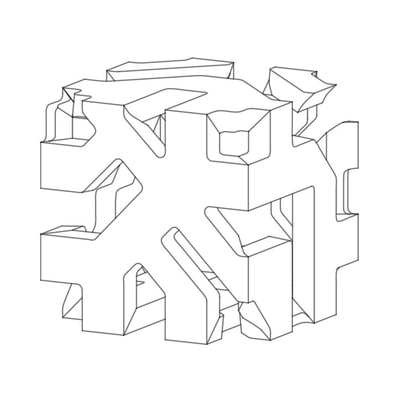

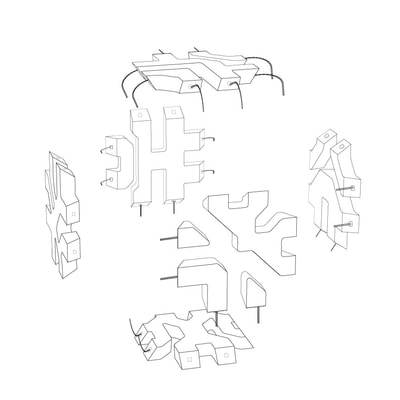

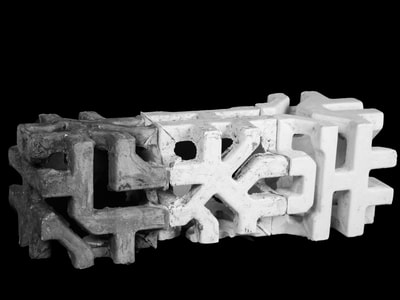

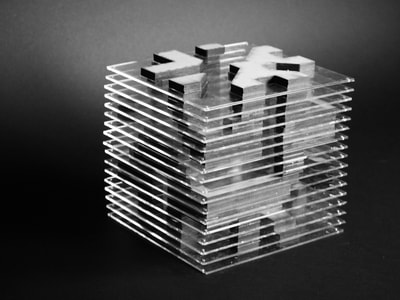

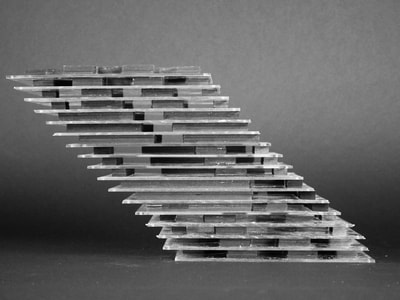

This fabrication endeavor began with the idea of creating a modular object that allowed for scalar and visual variation through means of a full 360 degree tessellation. It was important that the cube could be imagined at a variety of scales, as a stand alone object, or as an aggregation of hundreds of objects. The design process considered several positions that the object might encounter: ornament vs structure, light vs. shadow, aggregate vs. individual, etc. The objects behavior in relation to these conditions was curated and examined through both the digital and physical mediums.

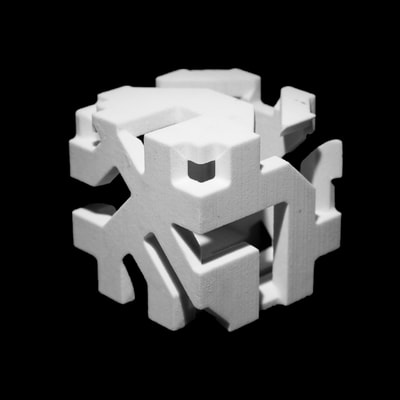

In the digital, the spacial qualities were examined by expressing the object in different environments, programs, or employments. Physically, the object was manifested in two methods of fabrication, 3D printing and casting. The connectivity was measured through the smaller 4" 3D printed cubes. The structural quality was better understood through the casting process. Casting was tested in both Rockite and Plaster and the form work was produced with CNC cuts into high density foam.

In the digital, the spacial qualities were examined by expressing the object in different environments, programs, or employments. Physically, the object was manifested in two methods of fabrication, 3D printing and casting. The connectivity was measured through the smaller 4" 3D printed cubes. The structural quality was better understood through the casting process. Casting was tested in both Rockite and Plaster and the form work was produced with CNC cuts into high density foam.